How to Fire Up an Easy Fire Ll Kiln

Please note: Not all kiln options are available on all L&L kilns. Specific options available for this kiln can be checked in the drop down options above.

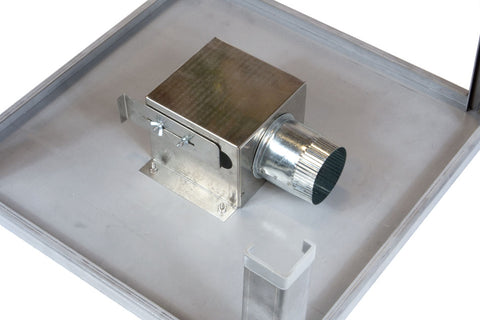

Rolling Stand

L&L's rolling kiln stand features heavy gauge (14 ga) galvannealed steel construction with multiple bends for extra strength, steel swivel locking casters, integrated vent collection box support, and guide rails for the kiln. Each size is fitted to the kiln. Important special caution plates are riveted to three sides of the stand. The vent collection box is not included but, when you order a Vent-Sure vent system the longer duct is included with the system.

E-Quad Element Option

Large Diameter Elements With Thick Wire And Lower Watt Density

- The Quad element system provides four rows of elements in one 9" high section.

- The combination of large 1/2" diameter element coils (most non-L&L elements are only 1/3" in diameter), the doubled surface area of the Quad element design, and superior heat transfer of L&L's patented ceramic element holders, make this the best element system in the world today.

- Used on JH Series kilns for several years now - under the rigorous conditions of high temperature crystalline glaze firing - element life of over 130 firings with standard A-1 alloy have been normal. In another example, on an eQuad-Pro, with three sets of elements being used, one customer got 232 firings to Cone 5 per element set.

- Increased surface area of our Quad element system results in more even firings.

- Quad elements are more cost effective than APM elements for high-fire work. Combine Quad and APM for the ultimate in element life.

Available As An Option On These Kilns -Easy-Fire, Easy-Fire XT, Jupiter, DaVinci, Liberty-Belle

Standard On These Kilns -eQuad-Pro, JH Series

Vent-Sure for 120 Volts or 220 Volts

A Critical Component In The Longevity Of Your Kiln!

The Vent-Sure automatic kiln vent helps prevent corrosion on the inside and outside of your kiln. It ensures that your kiln gets the longest possible life from your elements and electrical components. This is so important that, if you do not have a Vent-Sure installed on your kiln, the pro-rated element warranty is in a different category.

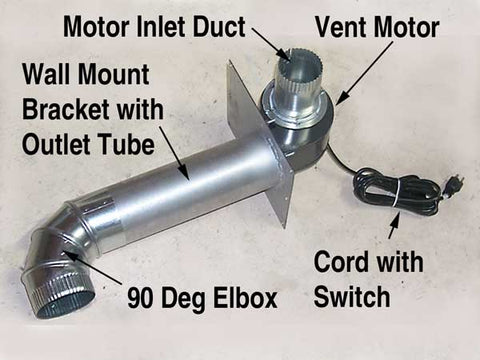

Vent Blower

- The vent blower motor is normally mounted with the 12" outlet protruding through the wall.

- This keeps the heat of the kiln away from the motor (for long motor life) and keeps the motor vibration away from the kiln (which can cause ware to move, damage to the kiln, and misfiring of cones on a Kiln Sitter - if you have one).

Vacuum Is Safer Than Pressure

- The vent tubing is kept under vacuum instead of pressure.

- This insures that any leak in the tubing does not blow noxious fumes into your room.

External Venting Is Better

- External venting is safer and surer than venting to the inside of your kiln room (even with a filter).

Large Capacity

- The blower vents up to 130 CFM (cubic feet per minute).

- This will handle up to a 20 cubic foot kiln (and usually larger). More than one vent can be attached to a kiln.

Minimal Electrical Power Needed

- The motor only pulls 1.37 amps at 120 Volts.

Six Foot Power Cord With On/Off Switch

- The blower motor features a 6 foot long 120 volt 15 amp power cord. An On/Off switch is located on the cord.

- 240 volt models are available.

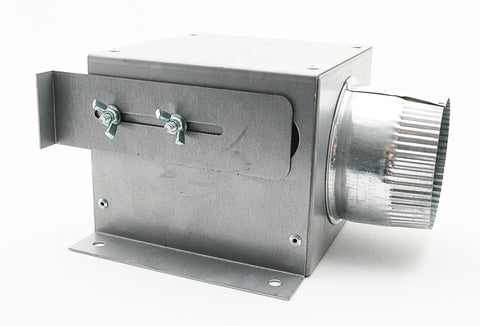

Adjustable Vent Control

- A vacuum bypass on the kiln bypass/collection box adjusts the amount of venting from the system.

- Don't waste heat and energy by venting more than you need.

- Adjust vent to kiln size.

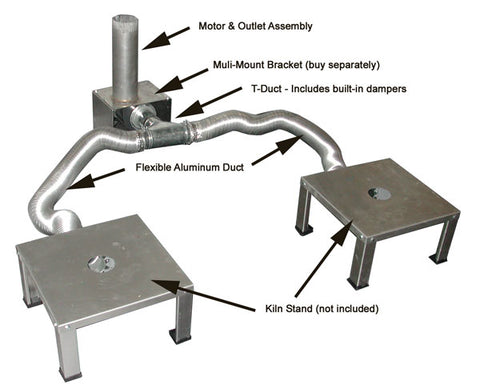

15 Feet Of Flexible Aluminum Duct

- 15 feet of flexible expandable aluminum 3" diameter duct is included along with necessary hose clamps.

- Longer lengths or lengths of 3" stove pipe can be used as well.

- Length can be as great as 60 feet horizontal or vertical with up to four 90 degree bends.

Three Year Limited Warranty

- Because of our unique wall-mount fan we rarely replace fan motors.

MET Listed To UL499 Standards

- The VENT-SURE Model VS-1 is c-MET-us listed for use with all c-MET-us listed L&L kilns. It is MET-us listed for all MET-us listed L&L kilns.

Optional Multi-Mounting Bracket

- A special Multi-mounting bracket (M-V-MULT/00) is available to mount the vent motor on the floor or point the outlet vertically for ceiling installations.

Optional Vent Doubler

You can get a Vent Doubler option (M-V-VENT/DB) which allow you to vent two kilns that are each up to 10 cubic feet.

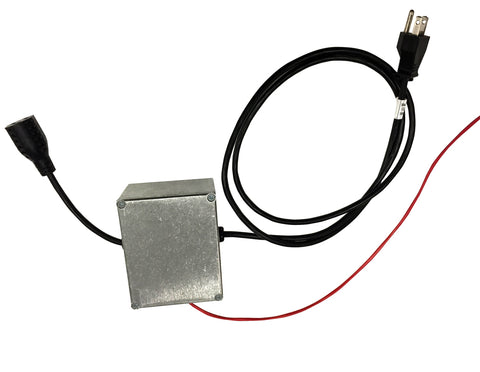

Optional Vent Controller To Turn Vent On And Off With DynaTrol

- The Vent Control will allow you to program the vent motor to turn on and off during the firing cycle.

Vent-Sure for 120 Volts (primarily used in the USA)

This is the complete 120 volt Vent-Sure System.

WHAT IS INCLUDED:

- One wall-mounted blower mounted on a bracket with a 12" long vent pipe to go through outside wall

- One Motor Inlet Duct

- An 6 foot power cord with an attached On/Off switch plugs into a 120 volt standard receptacle

- One Bypass Collection Box to be mounted to the kiln or on the kiln stand, with mounting hardware

- One length of flexible aluminum ducting (expands to 15 feet) with two hose clamps

- One 4" diameter 90 degree elbow (for outside the building)

Model: M-V-VENT/00

NOTE: Vents made by manufacturers other than L&L may not be listed to UL499 standards if used with an L&L kiln. The same is true in reverse - the L&L Vent-Sure is listed to UL499 standards only with L&L listed kilns. If you have any question please contact the manufacturer of your non-L&L vent system.

Click here for Specification Sheet

Click here for Instruction Manual

High Limit Control

- Bartlett High Limit Control with latching relay acts as a back up to the main DynaTrol control.

- You set a high limit temperature on this control for the kiln.

- If the DynaTrol fails for any reason then this acts as a "back stop" and shuts the kiln down.

- It latches in the closed position until the High Limit control is manually reset by pressing a button on the face of the control.

Back Up Contactor Option

- The normal configuration for the control breaks the power to the negative of the relays.

- However, you can also purchase this with back up contactors which will be completely redundant power contactors so that if one or more contactors fail in a closed position then the kiln still cannot climb above the High Limit set point.

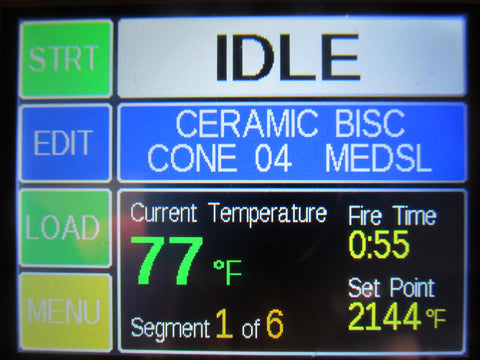

Genesis Touch Screen Control Option

9th Generation Bartlett Control!

The new Genesis control from Bartlett includes a touch screen interface and WIFI connectivity added to the proven software of the DynaTrol.

Highlights

- Touch-screen technology for the user interface

- Easy-to-follow screen descriptions

- Different user-interface levels, which can be set to match the user's firing knowledge

- Graphical display of the firing process right at the controller. This means you can graph the firing in real time and compare the program with actual results.

- Glass programs included.

- Store up to 12 custom user programs

- Up to 32 segments per program

- Ability to make adjustment during a firing such as add segments, add temperature, and skip segments

- Built in diagnostics testing for use with a current sensor

- Alarm

- Error Codes

- WiFi enabled for easy software updating. (Note KISS software is not needed for this to work). This works by connecting through a local WiFi connection to the Bartlett servers and downloading the latest software. It is very easy to do and requires no more than setting up your WiFi connection and pressing a few buttons.

- Compatible with KISS computer interface

Phone Add Now Available

Monitor your Bartlett Genesis controller with the Kiln Aid Phone app. Simply download the Kiln Aid phone app from your Android Play Store or Apple App Store, add your kiln, and begin monitoring as your kiln progresses through a firing. See these instructions on how to create an account.

Instruction Manual

Click here to get the complete instruction manual

KISS Starter Kit with USB Connection

STARTER KIT

You need one Kiss starter kit to connect one kiln to your computer. The starter kit includes:

- Kiss Software on CD.

- An opto-isolated RS232 to RS485 converter with power supply and USB output

- A 25 foot cable to connect between the computer and the kiln (add another telephone type extension cord to extend this)

- A modular panel connector to go on the kiln

- One RS485 communications chip to insert in the controller

Model: N-G-KISS/US

Kiln KISS Package for Extra Kilns

(For Adding Additional Kilns To Your Installation)

A Kiss kiln kit is needed for each additional kiln. The kiln kit includes:

- 25 foot cable

- A modular panel connector to install on the kiln

- An RS485 communications chip to install in the controller

- A duplex connector to daisy chain to the previous kiln.

Model: N-G-KISS/KK

Electronic High Limit Back Up Control

The High Limit Control is shown below the DynaTrol on the product photo.

High Limit Control

- Bartlett High Limit Control with latching relay acts as a back up to the main DynaTrol control.

- You set a high limit temperature on this control for the kiln.

- If the DynaTrol fails for any reason then this acts as a "back stop" and shuts the kiln down.

- It latches in the closed position until the High Limit control is manually reset by pressing a button on the face of the control.

Back Up Contactor Option

- The normal configuration for the control breaks the power to the negative of the relays.

- However, you can also purchase this with back up contactors which will be completely redundant power contactors so that if one or more contactors fail in a closed position then the kiln still cannot climb above the High Limit set point.

Pyrocil Metal Sheathed Industrial Thermocouple Upgrade

Where They Are Used?

- The industrial metal sheathed Type K thermocouples are available by special order.

- They are not as long lasting as our standard 8 gauge thermocouple when it is protected by the industrial mulllite protection tube.

- However, they do offer greater sensitivity to temperature change and so may be appropriate in applications that are below about 2200°F and require sensitivity (glass is a good example).

- Note that our standard 8 Gauge thermocouples with ceramic protection tubes use a +18 Deg F thermocouple offset which is programmed into the DynaTrol or One-Touch control. If you use these Pyrocil sheathed thermocouples start with a thermocouple offset of zero.

Technical Details

- L&L provides these thermocouples with a 1/4" diameter sheath. These will last longer than the smaller 1/8" diameter thermocouples that some manufactures use. We use a high quality ceramic terminal block on the end. They are 6-1/2" long.

- From our own extensive testing we found that this particular metal sheathing performed best of the available materials on the market under repeated Cone 10 firings.

Type-S Platinum Thermocouple Upgrade

The standard thermocouple used on the DynaTrol is Type K. The most common thermocouple configuration used is an 8 gauge exposed Type K thermocouple covered by a mullite ceramic protection tube (standard on Easy-Fire, Jupiter, Liberty-Belle, School-Master, Doll and DaVinci).

The Best High Temperature Thermocouple Is A Type S

- The very best thermocouple for constant high fire applications is a Type S platinum thermocouple with an alumina sheath.

- This is normally only recommended for the most extreme conditions (like firing crystalline glazes) because of its expense - or if the value or precision of your work is such that you do not want to risk thermocouple drift.

- You can special order a DynaTrol with Type S thermocouples. They are not available for the One-Touch™ control.

Technical Information

- Type S thermocouples are composed of a positive leg which is 90% platinum and 10% Rhodium, and a negative leg which is 100% platinum.

- It is usable from 32°F to 2700°F. (0°C to 1480°C).

- It has a different EMF output than Type K thermocouples (meaning the same temperature will produce different voltages to the control which must then be interpreted differently).

- That different scale requires both a simple hardware configuration change and a software change to take effect so it can not be done inadvertently.

- At temperatures used in pottery kilns (even the highest 2350°F) these thermocouples can last for a very long time (as long as they are not mechanically broken).

Retrofitting A Control With Type K Thermocouples

- This is not a retrofittable option on DynaTrols used before Jan 1, 2006.

- On the newer 700 DynaTrol boards it is possible to switch from Type K to Type S with a programming change and a jumper change.

- You MUST also change the thermocouple extension wire from Type K wire to Type S wire.

Description

- The Type S thermocouples that we provide have a 5/16" OD alumina sheath.

- They are ungrounded.

- There are two lengths.

- The short one used in the Easy-Fire, Jupiter and DaVinci kilns is 120mm (4.75") long.

- The long one used in the front-loading kilns like the Renaissance, Hercules and Easy-Load kilns is 160mm long (6.3").

- Termination is in a ceramic terminal block.

Which Thermocouples Are Used On Which Kilns?

- One 120mm thermocouple is used on the Doll

- Two 120mm thermocouples are used for any two section (18" high) Easy-Fire, Jupiter or DaVinci kiln

- Three 120mm thermocouples on all other Easy-Fire, Jupiter or Davinci kilns.

- EL2424 kilns use two. EL2427 and all other Easy-Load kilns use three. All front-loading kilns use 160mm TCs.

- Type S thermocouples are not available on the School-Master, Liberty-Belle, Doll or Renaissance kilns if fitted with a Bartlett 3 Button control or the One-Touch™ control.

- These are included as standard equipment on the JH Series Kilns.

Important Note

- If you have a Type S thermocouple or are retrofitting an older kiln with a Type S thermocouple the control must be configured for use with Type S thermocouples. If not the kiln could seriously overfire. See this for more information...

Positive Door Interlock Switch for Easy-Fire Kilns

All power is switched off with a 50 amp power switch before the door can physically be opened. (Easy-Fire only).

Model: K-E-LATC/00

Ceramic Fiber Lid for DaVinci Kilns

Ceramic Fiber Lids Are The Answer To Lid Cracking On Large Span Lids

- These are ideal for T3400 kilns.

- The lid firebrick is replaced with ceramic fiber modules.

- 2600°F ceramic fiber is folded and formed into 4" thick modules that have an alloy support system inside.

- The internal support of the module is stud-welded to a metal frame that matches the normal metal frame that we use in the firebrick lid.

- These lids will never crack or spall and will last indefinitely.

- The ceramic fiber is rated in temperature higher than the kiln rating so there is no concern about shrinkage of the fiber.

- These fiber lids are available as either new equipment or as retrofit kits to fit older kilns.

Warning: Refractory ceramic fiber has hazards associated with its use. Please see this current state analysis from NIOSH. Use a NIOSH approved dust mask when working with refractory ceramic fiber.

480 Volt Option

Technical Details For DaVinci And Jupiter JD2900 Kilns

- Standard DaVinci and JD2900 kilns have three elements per section. Elements are wired in a Star (Wye) Configuration to get 277 volts at the elements. This means the voltage potential in the kiln is much safer than it would be if the elements were running at 480 volts.

- On Quad versions we use two 240 volt elements in series.

- Power supply does not require a neutral (it is a "floating neutral).

- Watts are the same as 240-volt kilns. Amperage goes down.

- An optional NEMA 1 control panel is a special heavy-duty industrial control panel. These panels are floor standing on an included stand. They typically sit on the right side of the kiln. Note that you need the NEMA1 panel to get the MET-us listing. The price of the NEMA 1 panel is added to the price of the basic 480 volt option.

- Each kiln section is separately branch fused.

- A lighted "On/Off" switch is included.

- Kiln sections are "hard wired" (meaning that there are no plugs and receptacles) from the sections to the control panel with flexible "SO" cord (typically 72" long each).

- These 480 Volt kilns are c-MET-us listed to UL499 standards if the NEMA 1 panel is ordered.

- Click here for a PDF explaining on kiln electricity

Technical Details For Hercules And Easy-Load Front-Loading Kilns

- Elements are 240 volt elements wired in series. This means the voltage potential in the kiln is much safer than it would be if the elements were running at 480 volts.

- Power supply does not require a neutral.

- Watts are the same as 240-volt kilns. Amperage goes down.

- The control panel can be either a standard panel or a special heavy-duty industrial NEMA 1 control panel. The NEMA 1 panel is floor standing on an included stand. It typically sits on the right side of the kiln. Note that you need the NEMA1 panel to get the MET-us listing. The price of the NEMA 1 panel is added to the price of the basic 480 volt option.

- Each kiln section is separately branch fused.

- A lighted "On/Off" switch is included.

- These 480 Volt kilns are c-MET-us listed to UL499 standards if the NEMA 1 panel is ordered.

480 Volt Option

Technical Details For DaVinci And Jupiter JD2900 Kilns

- Standard DaVinci and JD2900 kilns have three elements per section. Elements are wired in a Star (Wye) Configuration to get 277 volts at the elements. This means the voltage potential in the kiln is much safer than it would be if the elements were running at 480 volts.

- On Quad versions we use two 240 volt elements in series.

- Power supply does not require a neutral (it is a "floating neutral).

- Watts are the same as 240-volt kilns. Amperage goes down.

- An optional NEMA 1 control panel is a special heavy-duty industrial control panel. These panels are floor standing on an included stand. They typically sit on the right side of the kiln. Note that you need the NEMA1 panel to get the MET-us listing. The price of the NEMA 1 panel is added to the price of the basic 480 volt option.

- Each kiln section is separately branch fused.

- A lighted "On/Off" switch is included.

- Kiln sections are "hard wired" (meaning that there are no plugs and receptacles) from the sections to the control panel with flexible "SO" cord (typically 72" long each).

- These 480 Volt kilns are c-MET-us listed to UL499 standards if the NEMA 1 panel is ordered.

- Click here for a PDF explaining on kiln electricity

Technical Details For Hercules And Easy-Load Front-Loading Kilns

- Elements are 240 volt elements wired in series. This means the voltage potential in the kiln is much safer than it would be if the elements were running at 480 volts.

- Power supply does not require a neutral.

- Watts are the same as 240-volt kilns. Amperage goes down.

- The control panel can be either a standard panel or a special heavy-duty industrial NEMA 1 control panel. The NEMA 1 panel is floor standing on an included stand. It typically sits on the right side of the kiln. Note that you need the NEMA1 panel to get the MET-us listing. The price of the NEMA 1 panel is added to the price of the basic 480 volt option.

- Each kiln section is separately branch fused.

- A lighted "On/Off" switch is included.

- These 480 Volt kilns are c-MET-us listed to UL499 standards if the NEMA 1 panel is ordered.

- Liberty-Belle kilns come with a NEMA 14-30 or NEMA 14-50 plug as standard.

- NEMA 6-30, NEMA 15-50, NEMA 6-50, NEMA 10-30 and NEMA 10-50 plugs are available for and extra fee.

Source: https://kruegerpottery.com/products/ll-easy-fire-e23s-3

0 Response to "How to Fire Up an Easy Fire Ll Kiln"

Post a Comment